Roman Concrete

February 20, 2023

As any

homeowner knows, a

house will fall into

ruin without continual

maintenance. As they say,

a stitch in time saves nine; so, that small

water leak under the

kitchen sink can lead to a

water damaged floor if not

repaired quickly enough. A well maintained house might have a

lifespan of a

century or two, and few structures will persist over

millennia. Only one of the

Seven Wonders of the Ancient World still exists. The remaining six were destroyed by such things as

fire and

earthquakes.

map of the Seven Wonders of the Ancient World. Despite its description and pictorial depiction in one of my childhood Golden Books, there's reason to believe that one of these, the Hanging Gardens of Babylon, did not really exist. (Map via the OpenStreetMap Foundation, released under the Open Data Commons Open Database License, and modified using Inkscape. Click for larger image.)

The

permanence of the

modern world is a consequence of the use of

concrete as a

building material. Water is the most used substance in our modern world, but concrete is the second. Concrete is formed as a

mixture of

cement and various

aggregates, such as

sand,

gravel, and

crushed stone. Sand is a preferred aggregate, since its small size leads to lesser need for the more

costly cement. As I wrote in a

previous article (Sand, October 18, 2021), concrete can't be made from

desert sand, since the

grains are too

smooth. The following table shows the tremendous quantities of cement manufactured in a single

year.[1-2]

Portland and Masonry Cement (2021)

| Country |

Thousand

Metric Tons |

Country |

Thousand

Metric Tonss |

| United States |

92,000 |

Brazil |

65,000 |

| China |

2,500,000 |

Egypt |

40,000 |

| India |

330,000 |

Indonesia |

66,000 |

| Iran |

62,000 |

Japan |

52,000 |

| South Korea |

48,000 |

Mexico |

50,000 |

| Russia |

56,000 |

Saudi Arabia |

55,000 |

| Turkey |

776,000 |

Vietnam |

100,000 |

| Other countries |

810,000 |

World total |

4,400,000 |

As can be seen from the table, China's need for cement is much larger than that for other countries; and, all that cement needs a like quantity of sand to make concrete. China had

dredged large quantities of sand from the

bed and

shores of

Poyang Lake in the Chinese

province of

Jiangxi, causing an

environmental disaster. Now, Chinese dredgers have been taking sand in the

territorial waters of

Taiwan,

Japan, and other countries.

Concrete has been used for more than three millennia. The

royal palace of

Tiryns,

Greece, which dates to around 1300 BC, had concrete

floors.[3]

Roman concrete, which was in common use from about 150 BC and possibly used a

century earlier, has been of special interest to

materials scientists because of its

durability and persistence to the present day. It's been written that "Roman-era concrete is the

iconic embodiment of long-term

physicochemical resilience."[4] There's even a

website dedicated to Roman concrete.[5]

Roman concrete is durable possibly from the incorporation of

volcanic ash, known as

pozzolanic ash (pulvis puteolanus), that prevents

crack propagation. As

Vitruvius (80-70 BC - post 15 BC), who famously stated that

architects deserve more

honor than

wrestlers, wrote in Book II, Chapter 6, of his

treatise,

De Architectura (On Architecture),[6]

Est etiam genus pulveris, quod efficit naturaliter res admirandas. nascitur in regionibus Baianis in agris municipiorum, quae sunt circa Vesuvium montem. quod commixtum cum calce et caemento non modo ceteris aedificiis praestat firmitates, sed etiam moles cum struuntur in mari, sub aqua solidescunt. hoc autem fieri hac ratione videtur, quod sub his montibus et terrae ferventes sunt et fontes crebri, qui non essent, si non in imo haberent aut e sulphure aut alumine aut bitumine ardentes maximos ignes. igitur penitus ignis et flammae vapor per intervenia permanans et ardens efficit levem eam terram, et ibi quod nascitur tofus exsurgens, est sine liquore. ergo cum tres res consimili ratione ignis vehementia foratae in unam pervenerint mixtionem, repente recepto liquore una cohaerescunt et celeriter umore duratae solidantur, neque eas fluctus neque vis aquae potest dissolvere.

There is a species of sand which, naturally, possesses extraordinary qualities. It is found about Baiae and the territory in the neighbourhood of Mount Vesuvius; if mixed with lime and rubble, it hardens as well under water as in ordinary buildings. This seems to arise from the hotness of the earth under these mountains, and the abundance of springs under their bases, which are heated either with sulphur, bitumen, or alum, and indicate very intense fire. The inward fire and heat of the flame which escapes and burns through the chinks, makes this earth light; the sand-stone (tophus), therefore, which is gathered in the neighbourhood, is dry and free from moisture. Since, then, three circumstances of a similar nature, arising from the intensity of the fire, combine in one mixture, as soon as moisture supervenes, they cohere and quickly harden through dampness; so that neither the waves nor the force of the water can disunite them.

The pozzolanic ash is an

aluminosilicate which reacts at

room temperature with

calcium hydroxide (Ca(OH)

2) and water. This reaction creates a cement of insoluble

calcium silicate hydrate and

calcium aluminate hydrate compounds. The reaction of

calcium silicate (Ca3SiO5) and water to produce calcium silicate hydrate (CaO.2SiO

2.4H

2O) and calcium hydroxide is as follows:

2Ca3SiO5 + 7H2O -> 3CaO·2SiO2·4H2O + 3Ca(OH)2

Core sample of Roman concrete from the Roman Theater of Augustus Caesar.

As can be seen from the core sample, the aggregates were typically far larger than those in modern concrete.

The Pantheon dome, the world's largest and oldest unreinforced concrete dome, is made from Roman concrete.

Unlike modern concrete, which achieves its highest strength within days, The strength of Roman concrete increases over several decades.

(Wikimedia Commons image by Millars.)

Binding additives to Roman concrete included

quicklime (calcium oxide, CaO) and

gypsum (Calcium sulfate, CaSO4). Examination of Roman concrete specimens revealed the existence of lime

clasts; that is, chunks of poorly mixed quicklime, which were just thought to be an indication of of poor aggregation

technique with no real consequence. However, a recent

open access article in

Science Advances indicates that this was a purposeful addition for added strength.[7-8]

The

research team included members from the

Massachusetts Institute of Technology (Cambridge, Massachusetts),

Harvard University (Cambridge, Massachusetts), the

Istituto Meccanica dei Materiali SA (Grancia, Switzerland), and

DMAT (Udine, Italy).[7]

The special durability of Roman concrete under harsh conditions, such as earthquakes, and its use as a

material for

aqueducts and

seawalls, has been a

mystery even under modern

scientific inquiry.[8] Its volcanic ash component from Pozzuoli, on the

Gulf of Naples, had always seemed to be the singular determinant of its strength.[8] However, large, aggregate-scale lumps of raw lime, known as lime clasts, are also a

ubiquitous and

conspicuous feature of the material.[7] The presence of these lime clasts, which are not present in modern concrete, have been attributed to some possible causes, such as improper

calcining of lime and insufficient mixing of the

mortar.[7-8] This new study suggests that these lime clasts give Roman concrete a

self-healing capability.[8]

It had been assumed that the lime incorporated into Roman concrete was first combined with water, in a process called

slaking, to form a highly

reactive paste-like calcium hydroxide (CaOH) from the quicklime calcium oxide.[8] However, slaked lime would not produce lime clasts; so, it appeared that Roman concrete was made using quicklime.[8]

Spectroscopic examination indicated exposure to high temperature, something expected from the

exothermic reaction involving quicklime.[7-8] Such hot-mixing contributed to the durability of Roman concrete.[7-8] This increased temperature significantly reduces setting times, and this would allow for faster construction.[8]

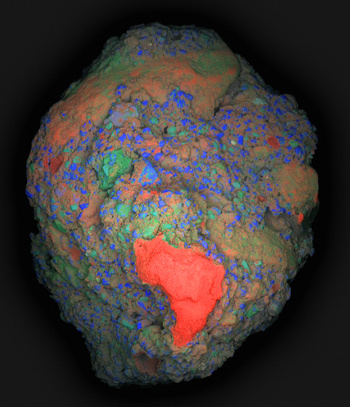

A large-area elemental map of a two centimeter fragment of ancient Roman concrete collected from the archaeological site of Privernum, Italy.

The color coding is calcium = red, silicon = blue, and aluminum = green).

A calcium-rich lime clast (red), is clearly visible in the lower region of the elemental map.

(Portion of an MIT image courtesy of the Roman concrete research team.)

The crack self-healing mechanism is based on the high

surface area lime clasts that act as a source of reactive calcium.[7] The high surface area arise from the

brittle nature of the lime inclusions that cause them to fracture into nanoparticules.[8] To verify this behavior, the researchers prepared their own cement mixture with the hot mixing method, and they found that cracks measuring up to 0.5

millimeter in

width would self-heal.[7] The lime, reacting with water, creates a

saturated solution of calcium that

recrystallizes as

calcium carbonate (CaCO3) to both fill cracks, or react with the volcanic ash.[8] In the

experiments, cracks healed within two

weeks in the simulated Roman concrete, but not in modern concrete.[8] The research team is working to

commercialize their modified cement material, which might be useful in the

3D-printing of concrete.[8]

References:

- Cement Statistics and Information, National Minerals Information Center, U.S. Department of the Interior.

- Mineral Commodity Summaries, Cement Statistics and Information 2022, United States Geological Survey.

- Amelia Carolina Sparavigna, "Ancient concrete works," arXiv, October 24, 2011.

- Jackson MacFarlane, Tiziana Vanorio, and Paulo J.M. Monteiro, "The Importance of the Ultra-alkaline Volcanic Nature of the Raw Materials to the Ductility of Roman Marine Concrete," arXiv, January 29, 2020

- David Moore, "The Roman Pantheon: The Triumph of Concrete," romanconcrete.com.

- Vitruvius Pollio, "De Architectura," F. Krohn, Lipsiae. B.G. Teubner. 1912 (via Tufts University Project Perseus). English translation, The Architecture of Marcus Vitruvius Pollio, translated by Joseph Gwilt, London: Priestley and Weale, 1826 (via the University of Chicago).

- Linda M. Seymour, Janille Maragh, Paolo Sabatini, Michel Di Tommaso, James C. Weaver, and Admir Masic, "Hot mixing: Mechanistic insights into the durability of ancient Roman concrete," Science Advances, vol. 9, no. 1 (January 6, 2023). This is an open access paper with a PDF file here.

- David L. Chandler, "Riddle solved: Why was Roman concrete so durable?" MIT Press Release, January 6, 2023.

Linked Keywords: Owner-occupier; homeowner; house; ruin; maintenance (technical); a stitch in time saves nine<; water leak; kitchen; sink; water damage; floor; service life; lifespan; century; millennia; Seven Wonders of the Ancient World; fire; earthquake; Great Pyramid of Giza; Hanging Gardens of Babylon; Statue of Zeus at Olympia; Temple of Artemis at Ephesus; Mausoleum at Halicarnassus; Colossus of Rhodes; Lighthouse of Alexandria; map; image; pictorial depiction; childhood; Western Publishing 1950s; Golden Books; OpenStreetMap Foundation; Open Data Commons Open Database License; Inkscape; permanence; modern history; modern world; concrete; building material; mixture; cement; construction aggregate; sand; gravel; crushed stone; cost; desert; sand; crystallite; grain; surface roughness; smooth; year; country; metric ton; United States; Brazil; China; Egypt; India; Indonesia; Iran; Japan; South Korea; Mexico; Russia; Saudi Arabia; Turkey; Vietnam; dredging; dredged; seabed; shore; Poyang Lake; province; Jiangxi; environmental disaster; territorial waters; Taiwan; Japan; head of state; royal; palace; Tiryns; Greece; floor; Roman concrete; century; materials scientist; durability; cultural icon; iconic embodiment; physical chemistry; physicochemical; resilience; website; volcanic ash; Pozzolana; pozzolanic ash; fracture; crack; fracture mechanics; propagation; Vitruvius (80-70 BC - post 15 BC); architect; accolade; honor; wrestling; wrestler; treatise; De Architectura; mineral species; Baiae; territory; Mount Vesuvius; lime (material); rubble; hardness; harden; heat; hotness; soil; earth; mountain; spring (hydrology); sulfur; sulphur; bitumen; alum; flame; fracture; chink; light mass; sandstone; arid; dry; moisture; coherence (physics); cohere; dampness; wind wave; force; aluminosilicate; room temperature; calcium hydroxide; calcium silicate hydrate; calcium silicate (Ca3SiO5); core sample; Theatre of Marcellus; Roman Theater of Augustus Caesar; construction aggregate; modern concrete; Pantheon, Rome; dome; reinforced concrete; strength of materials; decade; Museo del Teatro Romano de Caesaraugusta; Wikimedia Commons; Millars; binder; binding additive; quicklime (calcium oxide, CaO); gypsum (Calcium sulfate, CaSO4); clastic rock; clast; skill; technique; open access article; Science Advances; research; Massachusetts Institute of Technology (Cambridge, Massachusetts); Harvard University (Cambridge, Massachusetts); Istituto Meccanica dei Materiali SA (Grancia, Switzerland); DMAT (Udine, Italy); material; Roman aqueduct; seawall; unsolved problems in physics; mystery; science; scientific; scientific inquiry; Gulf of Naples; ubiquitous; conspicuous; calcination; calcining; mortar (masonry); self-healing material; slaking (geology); reactivity (chemistry); reactive; paste (rheology); calcium hydroxide (CaOH); spectroscopy; spectroscopic examination; exothermic reaction; large-area; chemical element; elemental; false color map; centimeter; fragment; archaeological site; Privernum, Italy; color code; color coding; calcium; red; silicon; blue; aluminum; greenlime (material); clastic rock; clast; surface area; brittleness; brittle nature; millimeter; width; solubility; saturated solution; crystallization; recrystallize; calcium carbonate (CaCO3); experiment; week; commercialization; commercialize; 3D-printing.