Graphene Friction

February 9, 2017

As we now routinely venture into the

nanoscale realm, we find that

nanoparticulate materials do not have the same

properties as their bulk counterparts, and small

machines do not behave as the larger versions. In essence, there's a limit to how much we can minimize familiar objects and materials and still obtain the properties we find for their "supersize" versions.

The

Greek philosophers,

Leucippus (fl. 5th cent. BC), and

Democritus (c.460-c.370 BC) were the first to argue that there's a limit beyond which

matter can't be reduced. This

idea, called

atomism from the

Greek words meaning "not-cutable," is now an accepted part of

modern science. It did, however, take 2,300 years to go from what was just an idea to an established scientific fact.

Leucippus is known only through the writings of Democritus, and much of what Democritus wrote is known to us only secondhand, such as mentions in the works of

Aristotle. As were other philosophers of his time, Democritus was interested in many

scholarly pursuits, including

music,

physics,

cosmology,

ethics, and

mathematics.[1] Democritus is said to have been the first to observe that a

cone inscribed in a

cylinder has one third the cylinder's

volume.

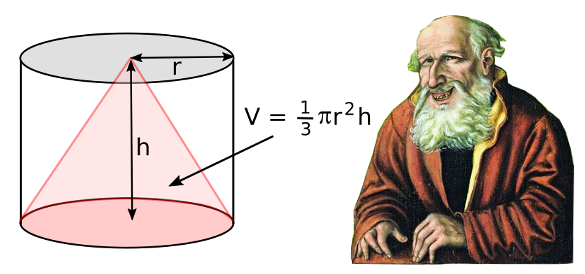

Democritus (c.460-c.370 BC) admiring his discovery of the volume of a cone inscribed in a cylinder. Democritus was known as the "laughing philosopher," since his philosophy emphasized happiness. This must be a good lifestyle, since he lived to be 90 years old. (Left image created using Inkscape. Right image from a 1538 painting by Franz Tymmermann (c. -1515-After 1540) at the Herzog August Library, via Wikimedia Commons.)

As if

progenitors of the expression, "

making something out of nothing," Leucippus and Democritus

theorized that the

natural world was built not just from

atoms, but from a

void as well. The void separates the atoms; and, as a result, atoms can combine for a time, but they cannot fuse. The different things that we see are special arrangements of atoms. This explains change in the world despite the permanence of matter. Aristotle, who was critical of Democritus' ideas, still praised the

logic of this

world system.[1]

While atoms have conveniently explained the properties of

crystalline matter, we have just recently been examining how very small assemblages of atoms interact with each other on the nanoscale. The darling nanoscale material of the past few

decades has been

graphene, and its importance is underscored by the short span of time between its discovery and the award of a

Nobel Prize to its discoverers.

Andre Geim and

Konstantin Novoselov published their first paper on graphene in 2004, and they received the

Nobel Prize in Physics in 2010.

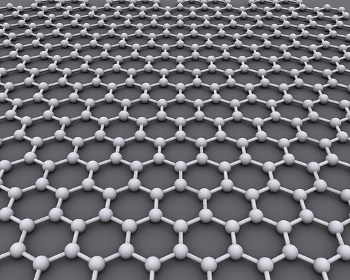

Pictorial representation of a graphene sheet.

(Image by Alexander Alus, via Wikimedia Commons.)

Graphite is used as a

dry lubricant, and

scientists are likewise interested in the

tribology of graphene, which is a single layer of graphite. As I wrote in an

earlier article (Friction, February 1, 2012), there have been some surprises. Scientists at the

National Institute of Standards and Technology (NIST) have conducted

friction experiments on graphene using

atomic force microscopy (AFM) by rubbing

AFM tips on single and multi-layer graphene sheets.[3-4]

The NIST experiments revealed that single layers of graphene have considerable friction, but the friction is reduced in graphene stacks. The

hypothesized explanation for this behavior is that the top layer of a graphene stack

deforms more when there are fewer layers beneath it.[4] For a single layer, this warping creates a

rolling resistance, so the friction is larger.[4]

An AFM tip moving on a four sheet stack of graphene in a NIST simulation.

Friction decreases as more layers are stacked.

(Image:

A Smolyanitsky/NIST))

A large international team of scientists from the

Xi'an Jiaotong University (Xi'an, China), the

Massachusetts Institute of Technology (Cambridge, Massachusetts), the

Karlsruhe Institute of Technology (Eggenstein-Leopoldshafen, Germany),

Tsinghua University (Beijing, China), the

University of Pennsylvania (Philadelphia, Pennsylvania), and the

Fraunhofer Institute for Mechanics of Materials (IWM, Freiburg, Germany), have continued studies on graphene friction. They published their findings in an article in

Nature at the end of 2016.[5-6] In this study, the

research team looked at the minuscule variation in friction as

atoms interact between the sliding surfaces.

This new study addresses not just the discovery that multi-layered graphene has less friction than a monolayer, but that the

static friction diminishes after travel over a few

atomic periods to then reach a constant value.[5] This

phenomenon has been seen, also, in the layered material,

molybdenum disulfide, but it has not been reproduced in

simulations.[5-6]

Contact area is known to be a factor in the interfacial friction between two

rough bodies, and for graphene it would be defined by the number of atoms within the range of

interatomic forces. For a given pair of materials, the nature of this contact can change during sliding to affect interfacial friction.[5] Says

Ju Li, a

professor in the MIT departments of

Nuclear Science and Engineering and

Materials Science and Engineering,

"There is this broad notion in tribology that friction depends on the true contact area - that is, the area where two materials are really in contact, down to the atomic level. The true contact area is often substantially smaller than it would otherwise appear to be if observed at larger size scales. Determining the true contact area is important for understanding not only the degree of friction between the pieces, but also other characteristics such as the electrical conduction or heat transfer."[6]

In the case of large objects, such as

machine gears, the actual amount of material contacting one gear with another is smaller than it appears, since the

gear teeth are rough and only the protruding points on the surfaces make contact.

Polished gears would be flatter, their contact area would be larger, and the friction would likewise be larger.[6] An accurate simulation would consider the true contact area.

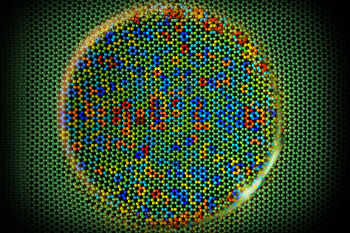

A computer simulation of graphene responding to a sliding silicon tip.

The colors specify the relative frictional forces arising from individual atoms.

(MIT image, used with permission.)

Using atomistic simulations, the research team was able to reproduce these experimental observations on graphene of layer-dependent friction and transient frictional

strengthening. The contact area was found to depend on how well atoms were aligned on the two contact surfaces, and on the

synchrony of these alignments during motion.[6] The atom-scale simulations revealed that the changes noted in static friction were a consequence of graphene's adjustment to the atomic forces made possible by its flexibility.[5]

It was further found that

pre-wrinkling the graphene sheets would change their tribology.[5] Says Li, "We can use that to vary the friction by a factor of three, while the true contact area barely changes."[6] It's supposed that these results will apply to other two-dimensional materials, such as

boron nitride and molybdenum disulfide.[6] This research was supported by the

National Science Foundation.[6]

References:

- Democritus, Stanford Encyclopedia of Philosophy, The Metaphysics Research Lab, Center for the Study of Language and Information (CSLI), Stanford University, December 2, 2016.

- K. S. Novoselov, A. K. Geim, S. V. Morozov, D. Jiang, Y. Zhang, S. V. Dubonos, I. V. Grigorieva and A. A. Firsov, "Electric Field Effect in Atomically Thin Carbon Films," Science, vol. 306, no. 5696 (October 22, 2004), pp. 666-669.

- Laura Ost, "Slippery When Stacked: NIST Theorists Quantify the Friction of Graphene," NIST Tech Beat, January 10, 2012.

- A. Smolyanitsky, J. P. Killgore and V. K. Tewary, "Effect of elastic deformation on frictional properties of few-layer graphene," Phys. Rev. B, vol. 85, no. 3 (2012), Document No. 035412 (6 pages).

- Suzhi Li, Qunyang Li, Robert W. Carpick. Peter Gumbsch, Xin Z. Liu, Xiangdong Ding, Jun Sun, and Ju Li, "The evolving quality of frictional contact with graphene," Nature. vol. 539, no. 7630 (November 24, 2016), pp. 541-545, doi:10.1038/nature20135

- David L. Chandler, "The science of friction on graphene," MIT Press Release, November 23, 2016.

Permanent Link to this article

Linked Keywords: Nanoscopic scale; nanoscale; nanoparticle; nanoparticulate; material; material properties; machine; Ancient Greek philosophy; Greek philosopher; Leucippus (fl. 5th cent. BC); Democritus (c.460-c.370 BC); matter; idea; atomism; Greek language; Greek word; modern science; Aristotle; scholarly method; scholar; music; physics; cosmology; ethics; mathematics; cone; cylinder; volume; happiness; lifestyle; Inkscape; >painting; Franz Tymmermann (c. -1515-After 1540); Herzog August Library; Wikimedia Commons; progenitor; making something out of nothing; theory; theorize; nature; natural world; atom; vacuum state; void; logic; cosmology; world system; crystal; crystalline; decade; graphene; Nobel Prize; Andre Geim; Konstantin Novoselov; scientific literature; publish; Nobel Prize in Physics; graphite; dry lubricant; scientist; tribology; National Institute of Standards and Technology (NIST); friction; experiment; atomic force microscopy (AFM); AFM tip; hypothesis; hypothesized; deformation; deform; rolling resistance; computer simulation; Xi'an Jiaotong University (Xi'an, China); Massachusetts Institute of Technology (Cambridge, Massachusetts); Karlsruhe Institute of Technology (Eggenstein-Leopoldshafen, Germany); Tsinghua University (Beijing, China); University of Pennsylvania (Philadelphia, Pennsylvania; Fraunhofer Institute for Mechanics of Materials (IWM, Freiburg, Germany); Nature; research; atom; static friction; atomic spacing; atomic period; phenomenon; molybdenum disulfide; contact area; surface roughness; rough; intermolecular force; interatomic force; Ju Li; professor; Nuclear Science and Engineering; Materials Science and Engineering; electrical conduction; heat transfer; machine gear; gear teeth; polished; silicon; frictional force; strengthening; synchronization; synchrony; wrinkling; boron nitride; National Science Foundation.