Smectic Martensite

May 5, 2016

One

phenomenon with which every

graduate student is familiar, independent of his field of study, is the fact that

professors will selectively emphasize in their teaching the topics with which they are most interested, or most familiar. That's why my

graduate course in

physical metallurgy had several

lectures devoted to

Ostwald ripening; and, why a course I had in

fracture mechanics had far too much information about

martensite, and the

martensitic transformation. I wrote about Ostwald ripening in an

earlier article (Is Religion becoming Extinct?, April 1, 2011).

As you've likely guessed, martensite is named after its discoverer, the

German metallurgist,

Adolf Martens (1850-1914). Martensite usually refers to an extremely

hard form of

steel possessing an unique

crystal structure, but the term is often used to describe other

alloys formed by a

martensitic transformation, a transformation forced to happen so quickly that the

atoms in the

material can't

diffuse into an

equilibrium state. For this reason, martensite is is not an equilibrium

phase; so, it does not appear on an

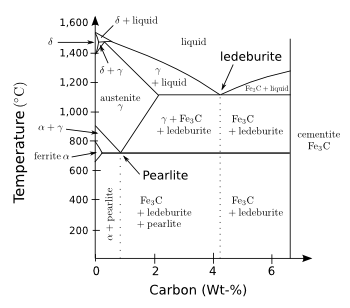

equilibrium phase diagram (see figure).

No Martensite here.

The iron-rich portion of the iron-carbon phase diagram.

(Modified Wikimedia Commons image by Christophe Dang Ngoc Chan.)

(Click for larger image.)

As the iron-carbon phase diagram above shows,

Fe3C (iron carbide, cementite) is an equilibrium phase formed when the

austenite (γ) phase is cooled below about 700

°C. If the cooling is too rapid, the carbon atoms are not able to diffuse through the solid to form cementite. Instead, they're locked into the

face-centered cubic lattice of austenite, which transforms into a

highly strained body-centered tetragonal form of

ferrite. Ferrite, as the phase diagram again shows, shouldn't have that much carbon, so it's

supersaturated with carbon and, therefore,

metastable.

Having too much carbon in a phase not capable of containing it is like trying to put

a square peg into a round hole, so something has to give. In this case, the material

deforms, creating a large number of

dislocations, and dislocations give steel its

strength. Martensitic steel can be nearly twice as hard as

pearlitic steel.

Since martensite is metastable, it will be lost with application of higher

temperature. A common

steelmaking technique is to create a steel with too much martensite, then

annealing it to produce enough martensite for the intended application. If martensite is so hard, why would you want to remove it? Hard materials are also

brittle, so you want your steel to be just hard enough, and not too brittle. That's why martensite was a topic in my fracture mechanics course.

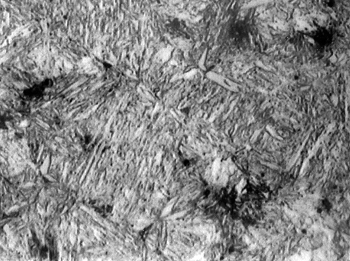

Metallograph of martensitic steel with 0.35% carbon, water-quenched from 870°C.

(Via Wikimedia Commons.)

The

grain structure of martensite appears also in

smectic-phase liquid crystals. In a recent paper in

Physical Review Letters,

physicists from

Cornell University (Ithaca, New York) have shown a connection between the smectic

microstructure, with its ordered patterns of

geometrically perfect

ellipses and

hyperbolas, and martensite.[1-2]

This type of microstructure arises when

nature needs to fill a

three-dimensional space with

conic sections under a specific set of

boundary conditions.[1] Interestingly, there's a similarity between the

mathematics required for this and the mathematics of

special relativity involved with

Lorentz transformations.[1]

The Cornell research team, led by physics professor,

James Sethna, calls smectic liquids "the world's weirdest martensite."[1-2] Their

computer modeling research made use of the extraordinary processing power available from the

graphics processing unit (GPU) integrated circuits normally used to speed

graphics for

video games. They developed a

clustering algorithm that demonstrated the similarity in the formation of the smectic liquid crystal and martensite microstructure.[2]

Says Sethna,

"This has been this puzzle for many years, and it finally has a suitably beautiful explanation... It ties together ideas from special relativity, and ideas from martensites, to explain this whole puzzle. It's aesthetically beautiful... there's a little bit of Euclidean geometry for those people who actually went to geometry class. It's like, 'Ellipses and hyperbolas, I remember those.' And you pour this (smectic) liquid and it forms these things."[2]

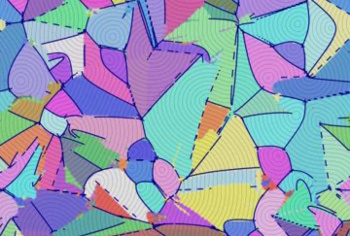

I would like to have this abstract art image hanging on my wall.

This is actually a simulation of a smectic microstructure.

(Cornell University image by the James Sethna Lab.)

The inspiration for this discovery came from an observation more than a

century ago by the

French physicist

Georges Friedel. In 1910, Friedel found that a fluid having equally spaced layers of

molecules will form ellipses and hyperbolas.[2] In filling three-dimensional space, concentric, equally spaced

spheres will form a point defect at the center. Another class of geometrical figures, the

cyclides of Dupin, will fill space with only ellipses and hyperbolas as defects. Friedel deduced the structure of his fluid by making the connection to the cyclides of Dupin.[2]

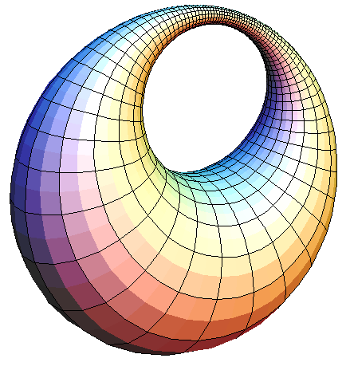

Ring cyclide generated by an inversion of a torus.

This image was generated in 2005, so you can see how far computer graphics has advanced since that time, aided by more powerful computers and GPU chips.

(Wikimedia Commons image by Xah Lee.)

Says Sethna, "Now we know that these cool cyclides follow the same rules as the crystals that fit together into martensitic steel."[2] This research was funded by the

U.S. Department of Energy and the

Simons Foundation.[2]

References:

- Danilo B. Liarte, Matthew Bierbaum, Ricardo A. Mosna, Randall D. Kamien, and James P. Sethna, "Weirdest Martensite: Smectic Liquid Crystal Microstructure and Weyl-Poincaré Invariance," Phys. Rev. Lett., vol. 116, no. 14 (April 8, 2016), article no. 147802, DOI:http://dx.doi.org/10.1103/PhysRevLett.116.147802.

- Daryl Lovell, "Weirdest martensite’: Century-old smectic riddle finally solved," Cornell University Press Release, April 14, 2016.

- Eric W. Weisstein, "Cyclide." From MathWorld--A Wolfram Web Resource.

Permanent Link to this article

Linked Keywords: Phenomenon; postgraduate education; graduate student; professor; graduate course; physical metallurgy; lecture; Ostwald ripening; fracture mechanics; martensite; diffusionless transformation; martensitic transformation; German; metallurgy; metallurgist; Adolf Martens (1850-1914); hardness; hard; steel; crystal structure; alloy; atom; material; diffusion; diffuse; thermodynamic equilibrium; phase; equilibrium phase diagram; iron; carbon; Wikimedia Commons; Christophe Dang Ngoc Chan; Fe3C (iron carbide, cementite); austenite; Celsius; °C; cubic crystal system; face-centered cubic; crystal structure; lattice; deformation; strain; tetragonal crystal system; body-centered tetragonal; ferrite; supersaturation; supersaturated; metastability; metastable; a square peg into a round hole; dislocation; ultimate tensile strength; pearlite; pearlitic steel; temperature; steelmaking; anneal; brittleness; brittle; metallography; metallograph; martensitic steel; quenching; water-quench; crystallite; grain structure; smectic-phase; liquid crystal; Physical Review Letters; physicist; Cornell University (Ithaca, New York); microstructure; geometry; geometrical; ellipse; hyperbola; nature; three-dimensional space; conic section; boundary value problem; boundary condition; mathematics; special relativity; Lorentz transformation; James Sethna; computer simulation; computer model; research; graphics processing unit (GPU); integrated circuit; computer graphics; video game; cluster analysis; clustering algorithm; puzzle; aesthetics; Euclidean geometry; abstract art; century; French; Georges Friedel; molecule; sphere; Dupin cyclide; cyclides of Dupin; point reflection; inversion; torus; computer graphics; computer; chip; U.S. Department of Energy; Simons Foundation.