Polymer-Carbon Nanotube Composites

March 28, 2011

The

mechanical properties of

metals and

ceramics have been reconciled with

theory for the simple fact that these materials are

crystals. Crystals have atoms regularly arranged in space, which makes a

mathematical treatment of their movements possible. It simplifies the required mathematics, although my graduate student experience with

dislocation theory[1] and

continuum mechanics[2] might belie that point.

The important distinction between ceramics and metals is that ceramics are

brittle and metals are

plastic. Each material behaves

elastically when small forces are applied; that is, they stretch in

proportion to the

force applied to them, and they regain their original shape when the force is removed. When larger forces are applied, a crack will initiate at a defect in the ceramic, and it breaks. Long before this breaking point happens in most metals, metals deform plastically; that is, they change shape irreversibly.

One useful property of metals is

strain hardening, which is also called work hardening or cold-working. A soft metal like

aluminum will become stiffer after repeated bending cycles. You may have casually experienced this effect yourself while bending pieces of aluminum

beverage cans. The mechanism for this strengthening is the collision of

dislocations in the metal crystal that prevents the slippage of one atomic plane over another.

Wrought iron was useful in many early applications for the simple reason that it could be cold-worked to increase its strength.

Woodcut from page 391 of De re metallica by Georgius Agricola (1556). This is a workshop with four men at various stages of metallurgical processing. Via Wikimedia Commons

Polymers are sometimes partially crystalline, but the

unit cells of such crystals are too large to provide any strain hardening. High strength polymers, such as

Kevlar, are strengthened by a different mechanism. Pulling strands of these polymers aligns the long

molecular chains to enhance intermolecular bonding. This strengthening mechanism is very useful, as many users of Kevlar

protective vests and

helmets have found.

Against this prior art comes a research result from

Rice University that demonstrates work hardening in a polymer-

carbon nanotube composite.[3-4] As an interesting aside to this story, this result is so unexpected that the

graduate student in the

Rice department of mechanical engineering and materials science who discovered this needed to fool his testing equipment into doing the measurements. His automatic machine was sure that there was something wrong with his specimens, and it would terminate its tests.[3]

The material is a composite of

polydimethylsiloxane (PDMS) and a "forest" of vertically aligned, multi-wall carbon nanotubes. PDMS is an inert, rubbery polymer. During cyclic testing of material specimens, the

stiffness was found to increase by 12% after 3.5 million

compressions, and it appeared that the stiffness would still increase with further cycling. In the "

round up the usual suspects" mode, the research team was able to rule-out enhanced

cross-linking in the polymer. Furthermore, there appears to be very little

chemical interaction between the PDMS and the carbon nanotubes, so the stiffening mechanism is unexplained. This research is reported in

ACS Nano.[4]

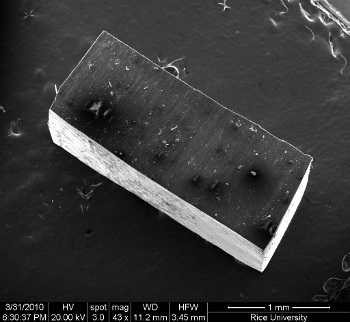

A small block of PDMS-MWCNT nanocomposite material.

(Image: Ajayan Lab/Rice University)

I'll now don my

conjectures cap, with the usual

caveat.

Bernd Matthias, who was a prominent

materials scientist of an earlier generation, proved to his own satisfaction that

experiments were a hundred times better than

theories. Matthias had once done a simple experiment that invalidated about a hundred published theoretical papers.[5] Undeterred by this precedent, I think I know what's happening in the material. Since the mechanism is not chemical, it must be

geometrical; viz., the presence of the nanotubes is allowing the mechanical cycling to bring the polymer chains into a more parallel alignment. This may mean, also, that the stiffening is

non-isotropic.

References:

- J.P. Hirth and J. Lothe, "Theory of dislocations," McGraw-Hill, 1968, 780 pages.

- Y.C. Fung, "Foundations of Solid Mechanics", Prentice Hall, 1965, 525 pages.

- Mike Williams, "Material adapts to strain," Rice University Press Release, March 23, 2011.

- Brent J. Carey, Prabir K. Patra†, Lijie Ci, Glaura G. Silva and Pulickel M. Ajayan, "Observation of Dynamic Strain Hardening in Polymer Nanocomposites," ACS Nano, Article ASAP Web Publication, March 16, 2011

- In reading the obituaries and recollections of Matthias after his death, I learned that he and I had the same criticism of the BCS theory of superconductivity. Theories, of course, should make predictions. In the case of superconductivity, Matthias and I thought that prediction should include telling us what materials will make better superconductors, which is something BCS does not do. BCS certainly didn't predict the YBCO high temperature superconductors.

Permanent Link to this article

Linked Keywords: Mechanical properties; metals; ceramics; theory; crystal; mathematics; dislocation theory; continuum mechanics; brittleness; brittle; plastic; elastic; Hooke's law; force; work hardening; strain hardening; aluminum; beverage can; dislocation; wrought iron; De Re Metallica; Wikimedia Commons; polymer; unit cell; Kevlar; molecular; personal armor; combat helmet; Rice University; carbon nanotube; graduate student; Rice department of mechanical engineering and materials science; polydimethylsiloxane; PDMS; stiffness; compressions; "round up the usual suspects"; cross-linking; chemical interaction; ACS Nano; conjecture; caveat; Bernd Matthias; materials scientist; experiment; theory; geometrical; non-isotropic; BCS theory of superconductivity; superconductivity; YBCO high temperature superconductors.